StressON Engineering

StressON Engineering

StressON Engineering

StressON Engineering

Capable of working in both online and offline modes.

Real-time production monitoring for improved operational efficiency.

Visualize metrics and trends for better decision-making with intuitive charts.

Customizable reporting and in-depth analysis through easy data export.

Reliable connectivity and seamless data transmission using Wi-Fi.

Collaborate with team members through diverse access levels.

Convenient USB pin for flexible power connectivity options.

Accurately detect objects within this range, providing flexibility for various measurements.

The sensor can operate on battery power for up to 36hrs before needing a recharge or replacement.

The sensor consumes 200 milliampere-hours of current, ensuring energy efficiency.

The sensor can connect to a Wi-Fi network within a 30-meter range for wireless data transmission.

The sensor requires the object to remain in the detection zone for at least 0.5 seconds to trigger detection.

The sensor is protected against dust and water jets, making it suitable for harsh environments.

Powered by a 5V direct current input through a microUSB connection for versatile power options.

Suitable for detecting both metallic and non-metallic objects.

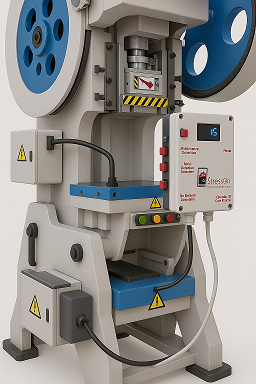

Suitable for detecting metallic objects and high speed process.

Focuses on providing real-time visibility into machine performance, Overall Equipment Effectiveness (OEE), downtime, and historical reporting. This helps manufacturers optimize their production processes and improve efficiency.

Real-time tracking of machine health and status, allowing maintenance managers and engineers to respond proactively to potential issues before they lead to machine failure or production downtime.

Uses machine data to diagnose, predict, and prevent potential failures, increasing equipment uptime. This predictive approach avoids the need for physical sensors by leveraging historical data and algorithms.

Aimed at improving workflows and production processes based on real-time insights. This empowers operators and process engineers to implement adjustments that enhance production efficiency and product quality.

In this application, we can collect the following data:

In this application, we can collect the following data:

In this application, we can collect the following data:

In this application, we can collect the following data:

Discover actionable insights that drive efficiency.