StressON Engineering

StressON Engineering

StressON Engineering

StressON Engineering

Empower your industry with cutting-edge IoT solutions for real-time production tracking and poultry farm monitoring. Optimize efficiency, minimize downtime, and enhance productivity with our smart monitoring technology.

Get Started Today!

Investing in StressON’s machine monitoring solutions offers unparalleled advantages to your business:

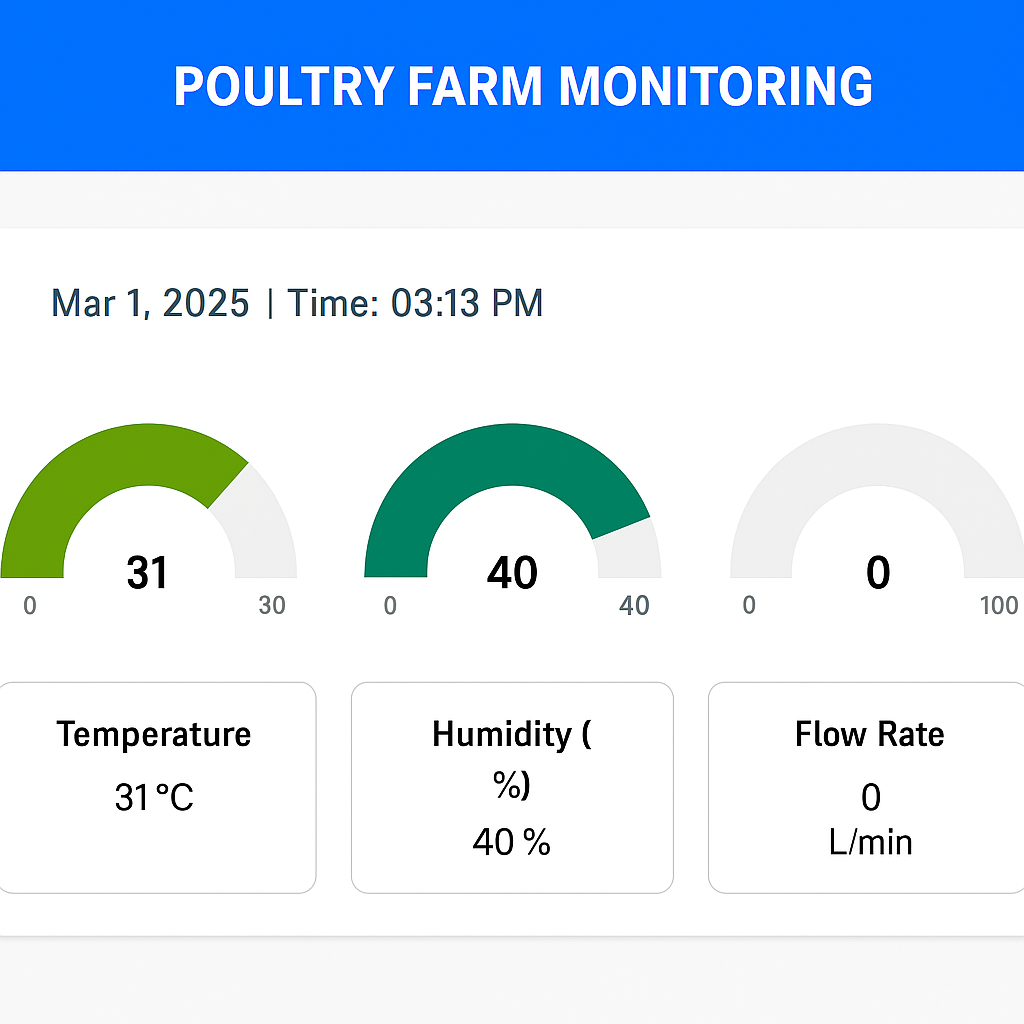

Revolutionize your poultry farm operations with our Poultry Farm Monitoring System. This innovative solution provides real-time data collection and analysis for:

Our Poultry Farm Monitoring System ensures healthier livestock, improved productivity, and reduced operational costs.

Easily gather data from any machine by connecting StressON’s Edge device to the machine's ethernet port. The Edge software processes machine data in real-time, securely streaming it to the cloud for analysis.

Monitor and manage machine status remotely, scaling across both modern and legacy equipment. Get a comprehensive view of downtime causes to improve equipment efficiency.

Track machine utilization hourly, daily, or monthly, uncovering hidden capacities and optimizing shop floor efficiency.

Leverage real-time diagnostics for condition-based maintenance, integrating with a CMMS to automatically generate work orders.

Empower operators with real-time performance data to meet production goals, addressing issues as they arise.

With StressON, you can track every detail on the shop floor—down to individual parts and work orders—helping to set accurate benchmarks for planning, quoting, and scheduling.

Utilize Pareto charts to report on downtime and quality issues, identifying the most common inefficiencies.

Evaluate production runs by comparing performance data across shifts, machines, cells, and operators.

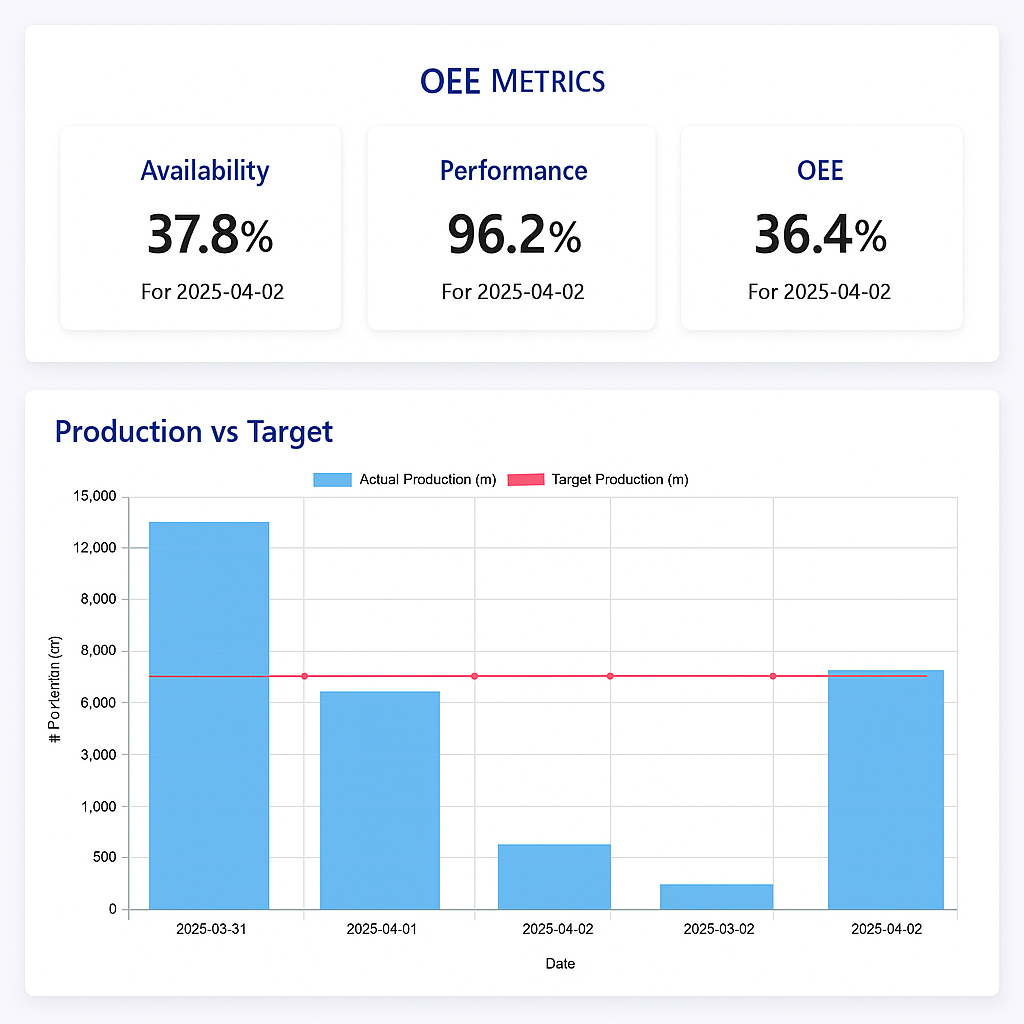

Analyze and optimize performance with real-time cycle data, ensuring improvements in machine availability, quality, and overall OEE metrics.

Enhance production efficiency by leveraging utilization analytics to uncover trends that highlight potential areas for improvement. These insights help you maximize your factory's capacity and streamline operations.

Achieve greater visibility into both operational processes and equipment performance with real-time dashboards, ensuring transparency across all levels of the factory floor. This data-driven approach facilitates informed decision-making and improves operational control.

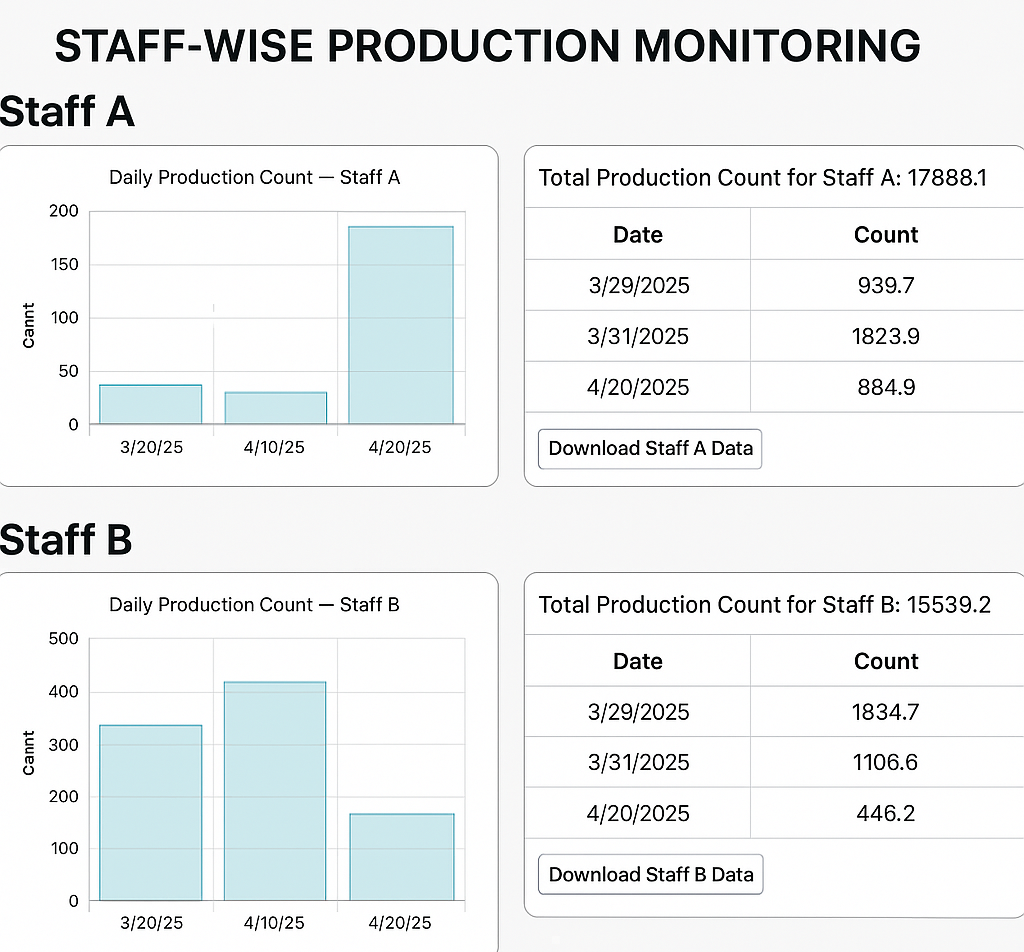

Introducing our advanced Smart Card Monitoring System, designed to empower your staff with real-time production tracking and performance analysis. This system enables:

With the Smart Card Monitoring System, you can ensure maximum efficiency and productivity across your workforce.

Discover actionable insights that drive efficiency.